Professional, top of the line painting equipment is used to achieve quality-controlled results. Specialising in painting to paint specifications, assures a quality end result. With attention to detail, industry experienced and qualified employees, Colvin Industries and Coatings Australia paint to each Code and Practice that is relevant in our field.

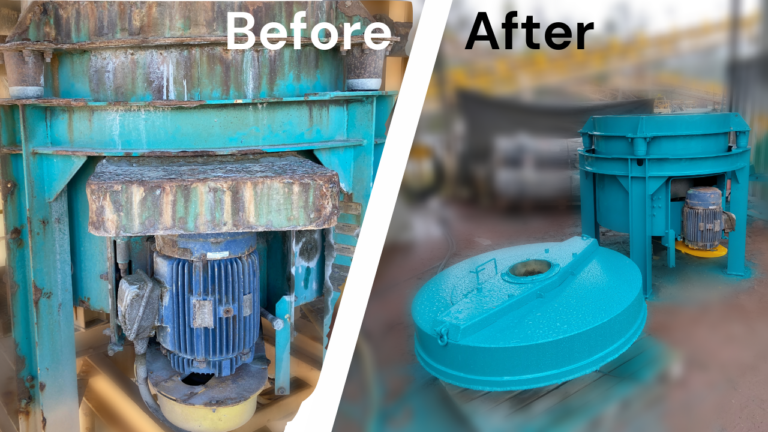

The industrial coating process involves applying a specialized paint over a metal surface to prevent the metal surface from corroding when the surrounding environment contains corrosive elements. Metals such as steel are protected from corrosion, rust, moisture, and other contaminants in the environment by such coatings. This extends the life of commercial and industrial equipment and infrastructure.

Paints Used By Colvin Industries For Industrial Coatings

Colvin Industries only use quality products that are designed for Australia’s harsh environment. When it comes to corrosion control of mining and industrial equipment it is crucial that quality paint is used. We primarily use Interzone 954 and Interzone 485 but have a paint for every industrial application.

AkzoNobel, an International Paints Company, offers various painting applications suitable for mines and the mining industry. These applications are designed to provide chemical and wear protection, durability, and safety in the harsh and demanding conditions often found in mining operations.

Corrosion Protection for Equipment: AkzoNobel offers corrosion-resistant coatings that can be applied to mining equipment, machinery, and structures to protect them from the corrosive effects of chemicals, moisture, and environmental factors. These coatings help extend the lifespan of equipment and reduce maintenance costs.

Protective Coatings for Infrastructure: Infrastructure within mines, such as pipelines, tanks, and structural steel, can be coated with high-performance protective paints to prevent rust and degradation. These coatings help maintain the integrity and safety of the infrastructure.